Link Trading

Professional Factory Audit Company in China.

NEED A FACTORY AUDIT?

- Truthful commission

- Many types of audit services and programmes

- ISO 9001, ISO 14001, and other certifications

- Professional factory auditors in China

- Any industry

Process Audit

Process audit verifies that processes are working as they should. It evaluates an operation or method at a factory establishment. It includes checking production accuracy, machinery accessibility, different production conditions, and inspects all the resources, employees, and the process.

System Audit

This is an audit conducted on a management system. Our team will audit the supplier to check compliance with various policies. It includes contract commitments, safety, and environmental regulations. Ethical and structural audits are part of this.

Performance Audit

This service is similar to system audit. However, process, product, and system audits are all conformance audits. They are designed to check how well a supplier conforms to regulations. Performance audits inspect the organizational improvements and efficiency of a factory. Link Trading will examine the general improvements and growth of your supplier in China.

Product Audit

During product audits, we will check the supplier’s compliance with your product or service. This is similar to product inspection, but more focused. Link Trading will make sure that your requirements are closely followed. Plus, we will check that product quality complies with government regulations.

Follow-up Audit

Based on the results of an audit, we may find issues. Once the manufacturer corrects these issues, we can conduct a follow-up audit to inspect the changes made. We will ensure that everything is in order and all modifications were made properly.

Social Compliance Audit

Social compliance audits are necessary for most supply chains, especially in China. This audit examines a factory’s environmental and social management, including labour policies and work ethics. The social compliance audit conforms to the SA 8000 standards. At Link Trading, we take this audit very seriously.

Security Audit

Security audits focus on a factory’s security systems and processes. This factory audit is aimed at improving safety, security, and reducing illegal trade. We will inspect various criteria, such as PIP, AEO, and C-TPAT. Link Trading is proud to conduct the Global Security Verification audit in China.

Fraquently Asked Question

With Link Trading, factory audits are easier than ever! You will just need to select your audit type service and approve our auditing plan. After this, we handle everything from conducting the audit to reporting it and developing corrective action.

We will conduct recalculations, performance tests, analytical procedures, interviews, and specific tests.

This is a four-step process: planning, execution, reporting, and follow-up.

Initially, we discuss with you what you would like us to check. Together, we plan and prepare everything to begin conducting a factory audit.

Then, our auditors conduct fieldwork where we audit the supplier’s factory in China. We summarize our findings in the factory audit report for your and the manufacturer’s viewing.

Finally, there is follow-up where we discuss the results of our factory audit. We talk about what needs to be modified and done in the future. We may also plan another audit after everything is corrected.

After an audit, if we find issues, we will report them to you and to the factory. The supplier will most likely plan corrective and preventive action to improve everything. We will then conduct a follow-up audit to check improvement. If the supplier does not listen to us, we will source you a new supplier in China.

Yes, you can! Checking client requirements is part of factory auditing, so you can help us plan the checklist and auditing tasks to suit your wishes.

We check many things. But here are the most notable ones:

- Factory profile

- Production process

- Quality management

- Official documents

- Equipment and machinery maintenance

- Facility conditions

- Employee training

- Labour policies

- Environmental policies

- Safety

We can conduct factory audits in any factory. Our trained auditors can inspect factories of any industry. It is our goal to be professionals in every field. There are audits in almost every sector of industry and they often assess the management system. In each case, there is a defined audit programme with specific criteria.

Any other question?

Feel Free to contact us, We're always here

More Specific Audits We Can Conduct

Be that plastic, electronic, or plush toys, Link Trading can conduct all the appropriate factory audits. We will examine raw materials, certifications, product safety, proper labelling, and ethics. You will receive an in-depth factory audit report. Together, we will ensure that your supplier and your goods are on track.

PET SUPPLIES AUDIT IN CHINA

Many households have at least one pet. This makes pet supplies a profitable industry with demand. Link Trading will source and audit the best pet products factory for your business. Pet supplies include cat trees, dog leashes, grooming brushes, transportation cages, bowls, toys, and more. We will check that the supplier has ISO 9001, environmental management, and other certifications. Our factory audits are strict so that your brand image is great.

If you want to sell cosmetic products, this audit is crucial for your business. There are several more specific regulations depending on the country. For example, the FDA standards in the US, or the ISO 22716:2007 internationally. We will ensure the quality and consistency of produced cosmetic products, as well as ethics, and more.

SNACK SUPPLIER AUDIT IN CHINA

This audit focuses on the regulations within the food and agriculture industries. We will check the hygiene and toxicity of food and equipment. Food is an important and high-stakes industry, so this audit is especially detailed. Some factory audits may need to conform to FDA standards as well. Whatever your needs are, we will build an audit around that.

HOUSEHOLD DEVICES AUDIT IN CHINA

Household devices include wireless phone chargers, mini speakers, fans, and more. These devices are ubiquitous in many homes, and so Link Trading developed skills in factory audits for these products. We will inspect safety, automation, storage, handling, testing, assembly, and more. Plus, our team can conduct environmental and structural factory audits as well.

Textiles and clothes from China are commonly exported around the world. And so, factory audit in apparel industries is important for Link Trading. Our professional auditors will check the ethics of work, quality, and more. We will examine everything from raw materials, and even interview employees. Your products may be baby clothes, casual menswear, formal dresses, and more.

SWIMMING ACCESSORIES AUDIT IN CHINA

Swimming accessories include masks, snorkeling equipment, goggles, pool floats, and more. In this category, we will audit waterproof qualities and toxicity of materials. To ensure that your swimming accessories are high-quality, we will also check necessary documentation and the factory work environment.

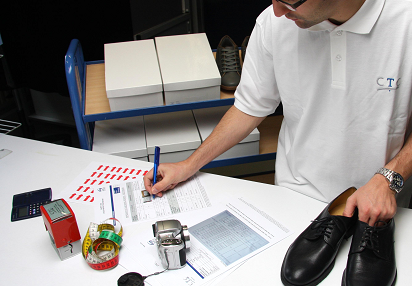

Link Trading will conduct factory audits for your shoe business. Our trained professionals will ensure that your China supplier is capable of providing quality footwear in due time. Compliance with your design and ethical work conditions are all part of such an audit. Whether you make heels or sneakers, our factory audit will cover everything.

Link Trading is an expert in factory audits. We will check that the supplier’s goods match your requirements of function, appearance, safety, and workmanship. We specialize in all sorts of jewelry audits, including precious and base metals, stone, pearls, shells, wood, acrylic, and leather. We will audit quality, good sourcing, compliance with standards, and more.

LED LIGHTS AUDIT IN CHINA

The LED light industry is very developed in China. LED lights are efficient and profitable. This is why sourcing and importing LED bulb from China makes for great business. We will audit processes, equipment, and products—all to ensure the quality of your LED lights.

The Most Responsible Factory Auditor In China

Sourcing from China is serious business. And so, we want to help you find the best supplier for your project. To make sure your products are taken care of, we conduct factory audits.

Auditing is an on-site validation activity, or inspection, of a process or quality system. We ensure compliance to different requirements. Some audits assess documents, risk, or performance. Some follow up on completed corrective actions. And some check general production conditions. An average audit may assess 50 different criteria.

Quality control may seem similar, but it is not. Audits are about long-term performance of the supplier, while inspections are more immediate. Factory audits also consider the big picture—how different aspects of factory work function together. Finally, factory audits create relationships, while inspections help make sure that production is on track.

Factory auditing is the last step of the sourcing process in China. An auditor examines financial information, official licenses and certifications.

Next, an auditor looks at the products made in the factory, the work flow, equipment, and employees.

An auditor will then conduct product inspection starting from raw materials to the finished product.

Finally, factory audits include social compliance issues where we look at whether the supplier follows government regulations. For example, SA 8000 and ISO 26000. All of this in-depth complete survey of the factory comprises a factory audit report.

Link Trading offers many types of factory audit services. This includes, process, product, system, and performance audits. All these supplier audits focus on various aspects of factory functioning.

Furthermore, we work with all sorts of industries and know the regulations. Each industry has many specific audits, and we cover them. There are ISO 13485:2016 and ISO 22716:2007 regulations, among many others.

To complicate matters more, different countries may have their own regulations. For example, the EU and the US have separate policies. So, depending on where you are importing products from China, factory auditing programmes may differ.

Link Trading is ready to sort all these complications for you! We are professionals with a goal of helping you develop your business.

No need to worry about all the rules and regulations; we will take care of everything. Just contact us with your product information and specifications!

A factory audit is essential to understand the capabilities of a supplier. Once your relationship begins, additional follow-up audits are great. This ensures that your manufacturer complies with all regulations and continually improves.

Regular audits will help you improve efficiency and build a better relationship with your supplier in China.

Plus, you will minimize risk in your supply chain.

Result?

You will be more confident in your supplier and products, helping you develop an amazing brand image.

Why wait?

Contact us today and schedule your China factory audit!

Factory Audit: The Ultimate FAQ Guide

Before importing from China factory, it is important you conduct factory audit.

To make the entire process easier for you, this guide will answer all questions you have about factory audit.

Let’s dive right in.

What is a Factory Audit?

A factory audit entails conducting thorough research and verification in a factory to ensure compliance with the required quality and standards.

Often, most buyers find themselves in compromising situations with suppliers.

This is owing to disappointments that come with trusting everything they are told concerning a product or service.

After your supplier has already convinced you enough to win your purchase, it’s always wise to do your due diligence and get to know the root of every operation involved.

You can choose to hire auditors who are skilled in identifying the key areas of improvement and advice you accordingly before commencing your purchase.

Why is a Factory Audit Important?

The truth of the matter is that the factory might respond “yes” to every question just to avoid much explanation on topics they are unsure of.

That’s where factory audit comes in and benefits you in the following ways;

- Confirms the factory’s existence – As more and more businesses are focusing on providing online services, verification of the factory should be a major consideration.

In the wake of such trends, more scams creep in and therefore an audit process will confirm the existence of the factory.

- A factory audit verifies the factory’s capacity to produce certain goods at a specified time.

The auditor evaluates how much goods the factory can produce during a certain period.

This in turn helps the business to understand the capability of the factory to meet its requirements.

- To authenticate the capability and skillfulness of the labor to produce the stated type and amount of goods.

The auditors conduct a thorough check-up on how goods are manufactured and produced paying attention to every detail.

This allows them to come up with clear and honest results regarding the competency of the workers and the factory in general.

- To get unbiased feedback – When a third party conducts a factory audit, there are zero chances of one-sided feedbacks.

- To know the performance of the factory – Factory audit provides information on every department of the factory and this aids in the decision-making processes for the buyer as well as the factory.

A factory audit is also important to suppliers as it not only provides trust to customers but also ensures quality improvement in the future.

What is the Difference Between a Factory Audit and an Inspection?

A factory audit and an inspection might sound similar but there is more to it than both of them ensuring compliance and verification of activities.

A factory audit is an authentication process performed in an institution, or a production step or function to realize quality assurance and compliance to set standards.

Both factory audits and inspections are conducted on-site.

factory audit

The difference between these two lies in the following;

- Factory audits are more focused on long-term goals while an inspection is normally limited to short-term requirements.

For instance, an auditor can assess the capability requirements of a given factory.

The main goal of a factory audit is to determine the production capacity of the factory which helps in defining any long-term business relationships.

Inspections are conducted to determine the quality and compliance of a given product at that particular time (short-term).

What I mean is that, let’s say you are importing items and you need a pre-shipment inspection done.

An inspection will be conducted to ensure that your goods meet the required standards and quality.

If not, you will be required to deal with the matter at hand at that moment.

- Audits help in creating proper relationships while inspections ensure that you are on track.

A social compliance audit will ensure matters such as working hours, health and safety standards, and proper management is upheld.

This will create a good working environment between you and the factory as you will be informed about the factory’s practices.

On the flipside, inspections are done after business relationships have already been established.

For instance, when doing a quality inspection, the inspector will authenticate whether the goods produced have met the required quality standards.

- Audits cover a broader spectrum as compared to inspection.

When conducting a quality assessment audit on a factory, the focus will not only major on manufacturing operations but also on the quality management system in general.

If we compare this to an inspection, you realize that inspections only focus on a specific manufacturing step or product quality.

- Audits are more complex as compared to inspection.

For instance, with an inspection, you might confirm whether all the goods are present.

If not, the missing goods will be brought.

An audit analyzes why some goods were missing.

What are the Common Types of Factory Audits?

The type of audit you will require will be determined by the type of goods you manufacture.

Below are some of the common types of audits.

- Structural audits – Structural audits are dedicated to surveying the building structures and ensuring safety and relevant codes and conditions have been met.

Not only does this ensure safety when working but also upholds employees’ health.

Additionally, a structural audit protects your brand’s reputation and averts any inconveniences in the supply chain.

structural audit

- Manufacturing audits – Just as the name implies, this type of audit focuses on finding out the capacity and capability of the factory to produce certain goods as per your requirements.

- Environmental audits –An environmental audit is meant to ensure environmental protection is upheld while goods are manufactured in the factory.

The auditors confirm that the factory abides by the laws and regulations regarding environmental protection.

environment audit

- Customs–Trade Partnership Against Terrorism Audit (C-TPAT) – Led by the US Customs and border protection, C-TPAT is aimed at enhancing security with much focus subjected to terrorism.

This not only reinforces security in the supply chain but also enhances security in U.S borders.

- Ethical audits – Ethical edits are meant to ensure that proper working conditions are being upheld.

This can be done as per the set international standards or be focused on a specific client.

Performing ethical audits will not only enhance your brand image but also curbs illegal subcontracting.

ethical audits

- Food supplier audits– As the name implies, this type of audits mainly applies to food suppliers.

The aim is to ensure that quality food is produced and proper hygiene measures are being adhered to.

Additionally, food supplier audits ensure that food safety is upheld and the factory meets the required standards.

food safety audit

What Elements does a Factory Audit Assess?

A factory audit assesses three major elements namely;

- Productivity – Assessing how products are produced will help in evaluating whether the supplier will meet production deadlines given a specific quantity to produce.

Analyze how long it takes to produce all products at a specified time frame.

Examine the equipment efficiency during the production process.

- Quality control – Assessing the quality management system of the factory allows you to verify that the work quality meets the required standards.

- Regulatory compliance– You need to understand that your suppliers can put your business and certifications at risk if they fail to adhere to the requirements.

Owing to this, it’s important to ensure that your suppliers conform to the required regulatory standards while delivering your products.

What is the Role of Factory Audits in Supplier Quality Management?

Supplier quality management involves assessing whether your suppliers can meet your needs by engaging them in some assessment processes before working with them.

To begin with, conducting a factory audit will help you improve supplier selection.

An auditor will conduct a quality audit on the supplier and analyze his or her capability.

Once they pass the audit your confidence in working with them will be stronger.

On the other hand, factory audits in supplier quality management will maintain your relationship with the supplier.

Audits assist in identifying problems earlier during the process level.

This prevents the development of the same problems at the shipment level.

How Can Factory Audit Benefit My Business?

Conducting frequents audits will benefit your business in several ways not excluding;

- Assessing the experience and expertise of the factory in the production of goods.

- Assessing the certification before the production process begins.

- A factory audit will also help in providing an overview of the current situation of the factory before the commencement of the production process.

- In addition to that, factory audits help to compare the potential of your manufacturer with others.

This is important when trying to single out the best among the rest.

- Reduces risks – Frequent factory audits help in identifying risks that may cause huge problems for your business.

Auditors will run thorough checks on every factory department and determine the non-compliances and risk factors that may affect your business.

- Enhances your brand image and protects your brand reputation – Factory audits build trust in your business and with this, people will have more trust in your business.

Keeping in mind that you work with qualified manufacturers or suppliers, thus your business reputation is upheld.

Generally, a factory audit is significant when selecting the best from the rest.

What is Not Covered in a Factory Audit?

A factory audit covers almost everything.

Nevertheless, the product quality is not normally covered keeping in mind that the audit happens before a buyer places an order.

Environmental practices as well as social compliance don’t form a major area of evaluation in a factory audit.

You should understand that a factory audit will primarily major on production capabilities as well as the quality management processes.

In addition to that, some factory audits also exclude both environmental standards and working conditions.

Should I just Do One Initial Audit or Do I need More?

In as much as one initial audit might seem to be enough, performing regular audits is important.

Regular audits ensure that your business productivity and efficiency are improved and risks are minimized.

In addition to that, you gain confidence in your quality assurance to your business associates and consumers.

Not forgetting that regular audits will ensure that your business is in line with the laws and regulations thereby allowing you to be at ease always.

How Do I Prioritize Suppliers for Auditing?

Conducting audits on all your suppliers might be such an overwhelming task.

This arises the need to give priority to the ones that need WS to contribute a larger percentage in the manufacturing process.

Regularly prioritizing suppliers at higher risk ensures that your quality standards are adhered to and this prevents any occurrence of shipment level problems later.

Do Conducting Social Audits on My Suppliers Make Me Socially Responsible?

No, it won’t.

It is important to understand that conducting social audits will not be a gateway to mending issues in society.

It is only meant to provide results and feedback on a particular area that you require information on.

With that in mind, if you don’t require the auditor to check out for malfunctioning machines in the factory, the auditor will not check them.

This will be evident once the audit report is released.

Having good audit criteria before the audit commences is key in ensuring that every aspect that you require checked is checked and nothing is left out.

Good criteria should complement your business goals and culture.

To ensure social accountability, your audits should be in line with your business customs.

What Are the steps to Conducting a Factory Audit?

1. Identify the Process to Audit

It is always better to start with less affected areas that have not reported performance problems then afterward proceed to the hard-hit areas.

2. Choose a Person to Conduct the Audit

The auditing crew should have good experience in their job and familiar with the specific audit process to be conducted.

3. Decide How Many Times you will Perform the Audit Process

The more problems discovered the higher the frequency of audit until confidence in that area is restored.

Regular audits should be a norm to ensure your business maintains the required quality standards and assurance to your customers.

Come up with an audit schedule and distribute it to each member of the auditing team.

Conduct the audit as you follow the audit schedule with proper commitment from all team members.

Write down any issues that are discovered during the auditing process.

Inform all the affected employees about the audit results.

Come up with correction suggestions to the identified issues.

Implement the corrective measures and actions to curb the repetition of the same problems.

Observe the corrective measures to determine if they were effective in eliminating the problems.

What is the Difference between Factory Audit and Assessment?

A factory audit involves authenticating and analyzing internal and external factors in a factory and ensuring they meet the required standards.

A factory assessment involves shallow internal checks performed in a factory mostly done in preparation for an audit.

An assessment gives a brief preview of the current state of your factory.

What is an Audit Report and why is it Important?

An audit report refers to written feedback based on the results of an assessment of a factory’s operations in regards to ensuring quality standards are maintained.

The auditor gives his or her opinion about the factory’s compliance with the set standards.

An audit report is important due to the following reasons;

- An audit report is helpful when looking for investors as it provides a guarantee that everything in the factory has been accessed and all issues are resolved.

This also raises your credit rating and business reputation.

Most clients will trust your business more upon realizing you work with qualified manufacturers or suppliers.

- It helps get a detailed review of the current reality of the factory which helps in decision-making procedures.

- A factory can make use of an audit report as evidence that the factory adheres to the set laws and regulations.

What are the Different Types of Audit Reports?

There are four main types of audit reports. Let’s have a look at them below;

Factory audit report

- Qualified opinion audit report– This report gives a summary confirming that most matters have been solved apart from a few issues.

This arises once the auditor is unsure of a specific process that can’t be issued with an unqualified report.

- Unqualified opinion audit report – every factory expects to receive an unqualified report at the end of every audit process.

This report gives positive feedback about the factory and it lacks material misstatements.

- Adverse opinion audit report – This is the most unwanted type of report that any factory wishes to get.

An adverse report has several problems outlined and would be a red flag to any future business associate in the supply chain.

- Disclaimer opinion audit report –A disclaimer report is given if the auditor is skeptical about providing their opinion owing to minimal cooperation from the factory management.

This might be as a result of lacking enough confidence in the audit that has been carried out owing to the factory’s limitation in the auditing process.

Also, a disclaimer report can be due to the lack of enough or rather satisfactory feedback from their queries.

What Should I look for in an Audit Report?

After being handed the audit report, the first thing to confirm is if there are any issues raised.

Once you have noticed some problems, request the supplier to provide you with a corrective action plan (CAP).

This will provide information on whether any actions have been taken to resolve the issues or the dates on which problem-solving will be finalized.

If the stated dates have elapsed, seek to find whether they have solved everything and ask for verification of the same.

An audit report contains the following information;

- Entire production process

- The total sum of all employees

- Major customers

- Machines used

- Shifts

- Time of operation

- The total sum of quality staff

- Subcontractors

- Peak production months

What is Verification?

Product inspection

Verification refers to an audit conducted as a follow-up process to ensure that problems found during auditing were resolved.

The auditor can choose to initiate a follow-up audit or work with the supplier in getting documents or photographs for desktop verification.

What are the Basic Principles of Auditing?

For a successful audit process to take place there must be principles to govern it. Some of these principles are not limited to;

- Skill and Competence – Every auditor should be skillful in their operations with adequate knowledge of current developments.

- Planning – Planning is an important process for any auditing procedure as it lays the base for the auditing process to take place.

The auditor’s work will run efficiently with a well-planned audit.

- Secrecy– The auditor must preserve information confidentially collected during auditing. Information should be shared only with the permission of the client.

- Honesty – An auditor should not take any sides and provide honest information regarding the audit process.

This is key in ensuring that the client’s business quality is upheld.

- Internal control system –A good internal control system in a factory aids the auditor to efficiently and effectively carry out the auditing process.

It helps him or her to decide on the procedure and timing to be used during the factory audit.

- Audit evidence – An auditor should collect every type of evidence that will be relevant to the audit process.

The evidence collected should have the following characteristics;

I. Completeness

II. Accuracy

III. Compliance processes

- Work done by others –Most of the auditing processes will require the auditor to analyze work done by other people.

The auditor is expected to highlight every source of these outcomes.

- The legal framework which is meant to safeguard the rights and interest of interested parties.

- Working papers – Just as the name implies, these are documents that contain the audit report. The auditor must safeguard them not forgetting that they can be used as audit pieces of evidence.

- Audit report – An audit report contains all information regarding the problematic and non-problematic areas of the factory.

What is a Checklist in Auditing?

A checklist refers to a tool that helps in counterchecking and ensuring that all business practices and processes are in line with the required standards.

A checklist outlines every detail that needs to be considered when conducting an auditing process.

Is Factory Audit the same as Supplier Evaluation?

Yes, it is.

Factory audit and supplier evaluation are two similar terms.

When auditing a factory you are evaluating the supplier’s compliance and non-compliance.

Both are meant to ensure that the factory provides outstanding and quality services while adhering to the set standards.

An audit or supplier evaluation will help to identify areas that need improvement and help solve issues identified.

How do I Prepare for a Factory Audit?

Before the initial preliminary audit, you need to first identify the areas that require auditing by reviewing the management as well as conducting an internal audit review.

Analyzing the factory’s Quality management system and preparing the documents that will be checked on site is part of it.

Quality management principles

Who Conducts Factory Audits?

Auditing can either be conducted by the employees of the factory or by a firm.

Internal audits are mostly conducted by the factory’s employees while the external ones are left for a third-party firm to handle the process.

Do Factory Audits Benefit Suppliers?

Yes, they do. Factory audits not only benefit the factory but also suppliers.

Suppliers can easily secure future business deals based on the audit report of a factory.

If the audit results are positive, the probability of securing more business deals is higher.

Are all Factory Audits of the same Standard?

No, they aren’t of similar standards.

Factory audits have different standards depending on what’s being analyzed.

For instance, ISO 9001, AS9100 is for the aerospace industry while ISO9001 is common among general consumer products industries.

What Shortcomings are there with Factory Audits?

In as much as factory audits are important, there are limitations to them which include;

- Cost – Auditing is not a cheap operation and therefore it requires a lot of funding.

This might pose a big challenge to small and medium-sized factories.

- Audit fraud– Acts such as bribery tamper with the accuracy of audits.

This is even more rampant in countries that have weak law enforcement on the supply chain. Weak enforcement institutions also contribute to such fraudulent practices.

- Time constraints – Auditors are normally provided with deadlines in which they are supposed to provide audit feedback.

This gears them to prioritize essential tasks and in some cases, they might miss including important subjects or information in the audit report.

- Sampling – Sampling involves auditors using a small portion of the selected object or subject to be audited and draw a conclusion from it.

This might not represent the general population and thus might affect the accuracy of the factory audit report.

- The use of cheap components that are not in line with the client’s requirements might result in trust issues.

What are the Main Factory Audit Checklist Essentials?

Even though your supplier might have explained everything to you to get you convinced, it’s always wise to do your due diligence.

Seek to find out whether the said promises reflect what’s offered on the ground.

To carry this out, you will need an effective quality audit checklist which must include the following;

- The Quality management system.

- No tolerance requirements for extreme violations.

- Basic facilities as well as factory environment and equipment maintenance.

- In-production controls to identify any issues.

- Lab testing and third-party collaborations.

- HR recruitment and training operations.

- The structure of the factory as well as its management behavior.

- Engineering, research, and design capabilities.

- Controls of finished goods and inspection.

- Quality controls for raw materials used.

How Does a Factory Audit Checklist work?

A factory audit checklist has three main sections that are important in the auditing process.

These sections include;

- Quality assurance and technical questions

- Environmental audit questions

- Social/ Health and safety questions

The auditor uses this checklist to get more information on various sectors that are being audited in the factory.

The questions asked are meant to provide data that is needed for the identification of issues and the final audit report.

What Happens if Violations Are Found During a Factory Audit?

Once an auditor identifies a violation, he or she includes the information in the final audit report as a “fail” result.

Thereafter, the auditor addresses the issues and comes up with possible suggestions to solve them.

Do Factory Audit Companies accept Liability for Violations that Occur after a Factory Audit?

No, they don’t.

After completion of an auditing process which includes solving identified problems, the liability for violations shifts to the supplier.

Nevertheless, you need to understand that after completing the auditing processes, there is a grace period for problem-solving.

During this period the auditor observes whether the suggested solutions to the auditing issues are effective.

If they happen not to be solving the problem, the auditor will be responsible for making alternative suggestions.

Liability arises once the auditor fails to identify an issue or for misstatements made.

Will Buyer-Supplier Cooperation be Perfect Following a Factory Audit?

Nothing is perfect and neither is the buyer-supplier cooperation after an audit process.

The relationship between the buyer and supplier after auditing has been conducted can either be stronger or weaker.

For instance, if a positive audit report is presented at the end of the process, the buyer’s trust in the supplier will increase and so will the cooperation thrive.

On the flip side, if the audit report has several negativities there’s a higher chance that the buyer will shun away from working with the supplier.

How Long Does a Factory Audit Project Take?

Most audits take three months.

These periods are divided into the following;

- Planning -4 weeks

- Fieldwork -4 weeks

- Compiling audit report -4 weeks

Keep in mind that the auditors might also be attending to several other audits and thus they split the time between your project and others.

Is it Worth it to Audit a Small Factory?

Auditing a small factory is not worth it. Instead, seek to evaluate it by paying attention to the personality of the management.

The thing is, a small factory will always appear disorganized once a formal factory audit is conducted on it.

As such, factory audits are suited for the bigger factories as they are more advanced not only in their management scheme but also in adherence to standards.

This is because they frequently deal with large buyers and thus they have to always be in line with the required standards.

How do Factory Audit, Inspection, and Lab testing fit together?

Product inspection

Factory audit, inspection, and lab testing are three different terms that relate to each other when it comes to factory auditing.

Factory audit involves assessing a factory’s ability and capacity to run its operations while still adhering to the required standards.

A factory audit will not only pay attention to facilities and equipment used but also the management system of the factory.

Product inspection is aimed at analyzing goods and determining whether they meet the requirements.

This process not only involves assessing the product’s appearance and construction but also it’s functioning.

Laboratory testing involves taking a few sample products to the laboratory for scientific verification of whether they meet the required quality standards.

What are the Two Types of Consultants Available for Factory Auditing?

The two main types of consultants available for factory auditing include;

- A consultant to make the paperwork have a nice appearance.

- A consultant who improves the processes.

Do Factory Social Responsibility Audits focus on Social/Labor Issues Alone?

Yes, they do.

A social responsibility audit should purely concentrate on Social/Labor responsibilities.

Keep in mind that there are different types of audits and each one of them receives special focus.

Do Auditors state ‘Accepted’ or ‘Rejected’ to a Factory During Audit?

Auditors prepare a report and outline the non-compliances found.

Afterward, this will be addressed during the audit closing meeting to come up with possible problem-solving suggestions and solutions.

What is an Audit Scope?

An audit scope refers to the assessment of the activities to be done as well as the time taken by an audit process. Scope of an audit includes the following;

- Legal requirements

- Entity aspects

- Proper communication

- Reliable information

- Evaluation

- Test

- Comparison

- Judgments

Does the Scope of a Factory Audit include Audits at Sub-suppliers’ Facility?

Factory audit process

Yes, it does.

If the supplier is working with two factories both of them will be audited.

For instance, a supplier having sporty shoes manufactured by one factory and ladies’ heels manufactured by a different factory will require auditing for both factories.

Who Signs an Audit Report?

The only person responsible for signing an audit report is the auditor or the partner from the auditing firm.

How Much Does a Factory Audit Cost?

The cost of a factory audit will depend on several factors such as frequency of the audit and size of the factory among others.

A factory audit will cost you around $300 or more per day.

Most if not all auditors are unable to visit several factories in a day and therefore expect to pay around $300 for every supplier that you wish to audit.

What does a Factory Audit Quote Cover?

A factory audit quote generally includes the total sum of expenses that will be incurred during the auditing process.

The tasks to be performed are highlighted together with the cost and duration it will take to complete each one of the tasks.

Can a Factory Be Re-audited? How many Times?

Yes, a factory can be re-audited.

Factory re-audits have no time limits and therefore it can be done as many times as you wish until all issues are resolved.

If a Factory Passes an Audit, How Long will the Result Be Valid?

The results of a factory audit will be valid for two years.

Nevertheless, other audits might be valid until the completion of the follow-up audit which might take a year.

In case a follow-up audit lacks within the next 12 months, the audit is declared expired and a new audit will be required.

What is Non-compliance?

Non-compliance refers to the failure to meet or adhere to the required laws and regulations of a country, region, or institution.

For instance, some factories might fail to meet the required quality standards of particular goods.

In such a case they are said to be non-compliant.

How Serious are Non-Compliances in a Factory Audit?

Non-compliance can cause serious damages to your business if not looked into carefully.

Before I explain to you how far this might go, let’s first understand what non-compliance means.

Non-compliance is a term used to explain the failure to adhere to certain rules, regulations, and standards.

That said, non-compliance can cause risks such as;

- Damage to business reputation

- Heavy fines and penalties

- Legal actions

When working with a supplier, it’s important to gauge the risk levels of the non-compliances.

Ensure that your supplier is ethically compliant by asking the right questions and looking out for evidence.

This should be your first approach whenever you are trying to find a potential supplier.

How do I choose a Qualified and Trustworthy Factory Audit Company?

Think of an auditing company as a long-term business partner.

When selecting one, you need to ensure that you select one who is ready to work together for the success of your business.

To achieve this, there are certain qualities that you need to check out when selecting your factory auditing company.

Such qualities are not limited to;

- Experience –. Your auditing company should possess a high level of expertise and experience. The auditing team should be certified professionals who can effectively work on accounting and auditing tasks.

Working with such a team guarantees you credibility.

You can evaluate professionalism by checking the necessary documents to ensure they are qualified for the job.

- All-rounded auditing firm – Working with an auditing company that specializes in several fields is advantageous.

This will reduce the amount of money or time spent in acquiring and familiarizing with a new auditor.

Not forgetting that an all-rounded auditing company can carry out multiple tasks at the same time.

- Communication transparency – Communication transparency is very significant in ensuring that you are aware of every move that’s being carried out.

That said, it is vital to choose an audit company that values transparent communication for the smooth flow of the auditing process.

- Size of the firm – Assessing the capability of the company to work on your auditing report is important.

You need to ensure that the auditing company has an adequate number of skilled professionals.

By so doing, you are guaranteed an effective auditing process that will take the desired amount of time.

Having one person dealing with all your financial records will not only result in delayed results but also inefficiency in performing tasks.

- Technological application –In the current modern world, the use of technology is applied in several areas to make work easier and enhance accuracy.

An auditing company that lacks this in its auditing process misses out on important insights for your business.

- Quality assurance process – Your auditing company should demonstrate a high level of quality assurance.

Performing regular training on the audit partners is one of the several factors that contribute to quality work.

- Ongoing support for decision-making and growth – A good auditor will keep in contact throughout the year and provide future-focused business advice where need be.

- The fee charged – Cost is one of the top considerations when it comes to selecting your factory audit company.

Auditing is an expensive process.

Think of it as a form of investment that you are undertaking for the benefit of your business success.

In as much as the cost might seem high, it’s important not to overlook the quality of work you want.

Remember, you get what you pay for and this doesn’t exclude auditing.

Therefore, as long as you have verified that your auditing firm is up to standard it’s better to ensure that the audit fees are well agreed by both parties.

- The reputation of the auditing company – A firm with awards, testimonials as well as references have undoubtedly a good reputation.

These are some of the characteristics you should keep in mind when selecting a qualified and trustworthy factory audit company.

At what Stage Should I Book a Factory Audit?

You should book your factory audit before making an order of samples or making the official order.

Additionally, it’s advisable that you first request a quotation after contacting your supplier.

If you wish to have a factory audit, ensure that you make your booking early enough.

Can I visit the Supplier’s Factory myself?

Yes, you can pay a personal visit to the factory.

This is highly recommended since you will receive first-hand information.

Factory visits can either be done to confirm the terms of the order, price negotiation, or confirm raw materials used.

Aside from that, visiting the factory will be beneficial in the following ways;

- Build relationships – Visiting the supplier’s factory allows you to establish stronger bonds with your supplier for the benefit of future business deals.

- Confirm if your supplier is an actual manufacturer or a trading company– Some suppliers lie about being a manufacturing company but in the actual sense they are a trading company.

They believe that being recognized as a manufacturing company will bring them more business as opposed to a trading company.

Visiting the factory allows you to confirm this. Both trading and manufacturing companies are good to work with.

- Opportunity for effective negotiations– When visiting the factory by yourself, you will have the opportunity to meet face to face with your supplier.

This has a huge impact on price negotiations as it will be more effective as compared to online negotiations.

- Communication- Paying a factory visit also allows you to establish proper communication skills which have a great impact on your project’s success.

- Get a clear understanding of the manufacturing process – Once you visit the factory, you oversee the production process.

This helps you to know if your supplier has the required machines and expertise to produce your goods.

- Confirm the product details and raw material used in the production of the items.

At Link Trading, we will help you with all importation needs.

Whether you want to handle product inspection, product management or factory audit, Link Trading offers a perfect solution for you.

Contact us now for all you factory audit in China.